Always ensure that the vehicle is securely chocked on level ground before releasing the parking brake. Cage the spring brake or use a minimum hold off pressure of 90 psi (6 bar).

Regular brake inspection is an important part of vehicle maintenance and should take place every 3 months.

These check frequencies are a minimum and, depending on the vehicle application, a more frequent check may be necessary. Refer also to vehicle manufacturer’s instructions with regard to check frequencies and service intervals for brake calipers, brake pads, brake discs and air chambers.

Brake Pad Wear

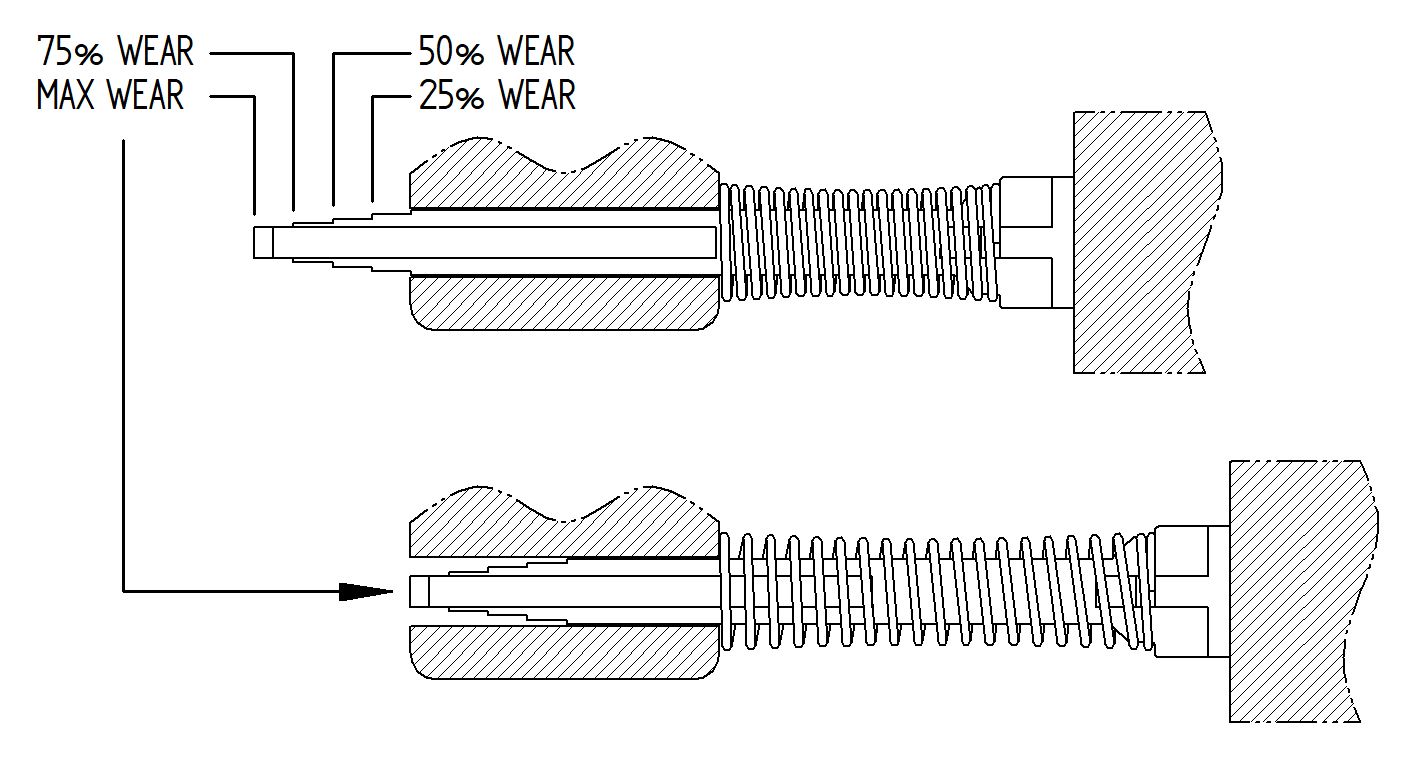

A visual assessment of brake pad wear should be made – independent of any wear indicator fitted to the vehicle. Most N-series brakes include a visual wear indicator for carrying out a quick and simple assessment of the approximate pad life remaining without removing the wheel. In a new pad condition the end of the indicator will extend past the bore in the housing. As the pads wear the length of indicator visible will reduce, and the indicator is incremented to the level of pad wear.

Before using the visual wear indicator to assess pad lining wear it is important to check that it is not seized in the housing. To do this pull and rotate the end of the wear indicator by hand against the spring force.

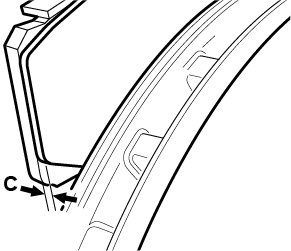

If the visual assessment indicates the pads are approaching their maximum wear allowance then a full check with wheel removed should be made. Brake pads should be replaced when the friction lining C has worn to a thickness of 3.0 mm or less.

! You must always replace the brake pads on both brakes across an axle. Only use the brake pads that have been approved by the vehicle manufacturer.

Corrosion

Visually inspect the brake for damage or corrosion, paying particular attention to the guide sleeve boots and tappet boots. Check that the adjuster cap is correctly fitted. If in doubt follow the additional checks in this maintenance procedure and if necessary replace any damaged parts using the relevant MEI service kit.

Guide Sleeve Boots

|

|

Tappet Boots

|

|

Brake Disc

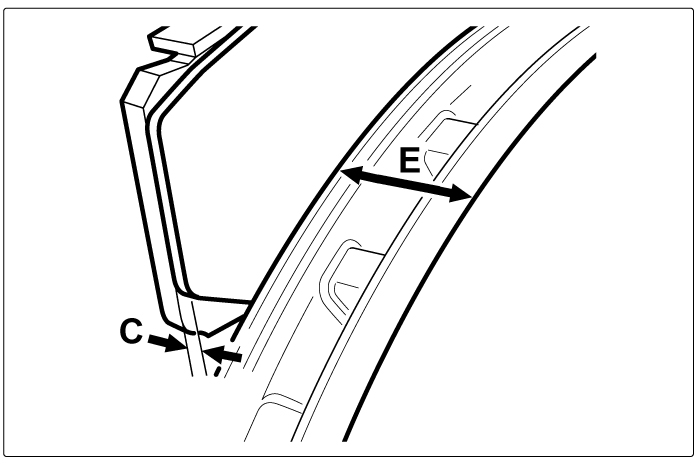

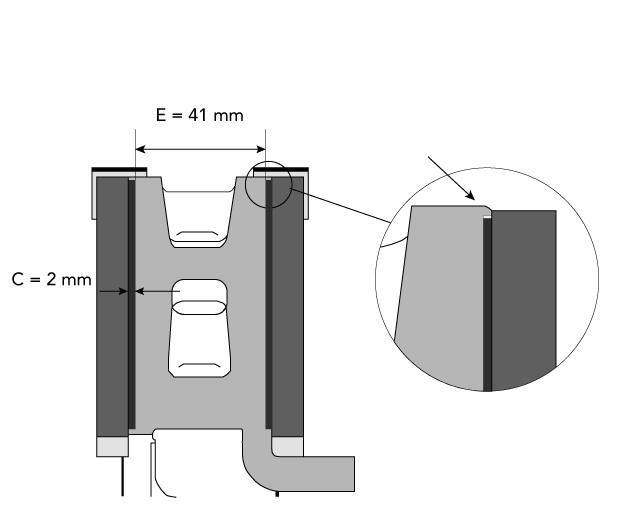

Measure the thickness of the brake disc at its thinnest section – brake discs should be replaced when the overall thickness E has worn to 39.0 mm or below.

! Be aware of possible burrs or lips at the outer edge when checking the disc thickness.

Note: The brake discs should be checked according to the vehicle manufacturer’s specification, looking for signs of heavy grooving, cracking or corrosion.

|

|

If disc thickness E is less than 41 mm it is recommended that the disc should be replaced when the brake pads are changed.

! You must always replace the brake discs on both wheels across an axle. Ensure old brake pads and discs are disposed of in accordance with local environmental regulations.